Colour selection guide

Selecting the right colour and surface finish for your joinery can be crucial to its longevity and may even impact whether or not your windows and doors are covered under warranty. Our simple step-by-step guide will help you through this process.

Step 1: Choose the right product for your project:

- Consider your environment and site conditions, especially if your home is coastal. Your site location will determine the performance requirements of the surface finish.

Step 2: Choose the right colour:

- There are a number of options to choose from. A good place to start is the Top 6 Trending colours.

- If you want a colour that is not in the Popular range, please discuss with your local Fisher® Windows consultant.

Step 3: Speak to your local Fisher® Windows consultant:

- Consult with your local Fisher® Windows Fabricator for further advice and to request an individual colour swatch.

- A word to the wise: when you are making your final colour selection, always assess your colour swatch in natural light.

Powder coat colours

Altus Window Systems offers an inspiring range of colours designed for powder-coated aluminium joinery, reflecting modern design trends and providing flexibility to suit any home or commercial style.

With 36 key colours and hundreds more available on request, including vibrant options for standout Stellar Doors®, our finishes – available in matte, gloss, flat, pearlescent, and textured – seamlessly complement cladding, roofing, and guttering.

Partnering with leading New Zealand powder suppliers Dulux and Akzo Nobel (Interpon), we ensure high-quality, durable finishes. Your local Fisher® Windows fabricator can provide a colour booklet, card, or swatches to help you choose the perfect shade.

Choose the right product for your project:

DURALLOY®

- Residential buildings and light commercial, less than 4 levels

- Properties greater than 10 metres from high tide level

PROTEXTURE®

- Residential buildings and light commercial, less than 4 levels

- Environments where high mar and scuff resistance is required

- Properties greater than 10 metres from high tide level

DURATEC®

- All residential buildings and commercial

- Properties greater than 10 metres from high tide level

CHARISMA™

- Residential buildings and light commercial, less than 4 levels

- Properties greater than 10 metres from high tide level

Our standard colour range is split into three easy sections:

New Zealand’s Top 6 Trending colours

As the name suggests these are the nation’s 6 most popular colours

New Zealand’s Popular colours

These are the 30 next most popular colours. If you can’t find what you’re looking for here please speak to your local Fisher® Windows consultant.

New Zealand’s Favourite Bright colours

This is a collection of the most popular bold and vibrant bright colours, typically associated with our Stellar Doors® range of entrance doors.

ColourScape™ Top 6 Trending colours brochure

ColourScape™ full range brochure

Dulux Charisma™ Black Ace (90C9116F)

The Charisma™ flat matt range features contemporary, solid colours in a flat matt finish for a subtle and sophisticated look. The range is ideal for residential and commercial buildings in environments greater than 10m from the high tide mark and mild to severe exterior conditions.

Whilst this colour range is fantastic, feedback from customers has alerted us to the fact that joinery finished in Black Ace does need to be handled with care and maintained as per Dulux instructions. Namely, protective wrapping should be kept in place right up until installation followed by a regular six-monthly cleaning programme. Sheltered areas can have a higher risk of coating degradation as wind-blown salt and other debris or pollutants may adhere to the surface and not wash away when it rains. These areas may require more frequent cleaning.

Please bear this in mind when choosing the colours for your next project.

A quick note on powder coating thermal strips

Thermally broken windows in New Zealand are manufactured using two main technologies: polyamide strip insertion and the Pour-and-Debridge method. Altus is the only manufacturer in the country to offer both solutions — a capability we’ve maintained for over 20 years. It’s one of the reasons we consider ourselves experts in thermal break technology.

Both methods are designed to improve energy efficiency by reducing the transfer of heat and cold through the aluminium frame. This is achieved by inserting an insulating barrier between the internal and external elements of the profile.

In the case of polyamide strips, these are inserted in long lengths and mechanically crimped between two aluminium sections prior to powder coating.

Powder coating is an electrostatic process where a fine resin powder is applied to the profile, then cured in a high-temperature oven to bond the coating to the aluminium. While the aluminium component of the frame remains unaffected by the heat, the polyamide strip may react slightly. Although this reaction does not compromise the durability or thermal performance of the strip, it can result in subtle surface variations — such as differences in sheen, colour tone, or texture — between the strip and the aluminium.

These visual or textural differences vary depending on the powder formulation used and are purely cosmetic. They are not defects, nor do they affect the performance of the window. As such, they are not considered valid grounds for a warranty claim.

But you don’t have to take our word for it – the Window and Glass Association of New Zealand provides a detailed explanation of this process and its potential outcomes on their website. Read more about it here.

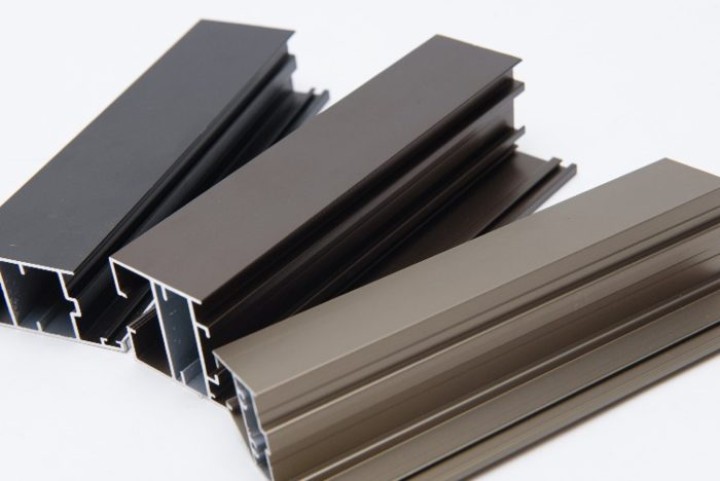

Anodised colours

Anodising provides a highly durable, colour fast coating for aluminium. It is available in five colours and offers a reliable alternative to powder coating.

Altus Window Systems offers Matt Etch anodising on orders to 12, 20 and 25 micron. Ask your local Fisher® Windows consultant about the availability of Anodising in Natural, Light Bronze, Medium Bronze, Dark Bronze and Black as defined by the Window and Glass Association of NZ Standard.

Matt Etch is a finish which can help remove manufacturing lines and imperfections, delivering a fine matte surface, sharp clarity and reduced reflectivity.